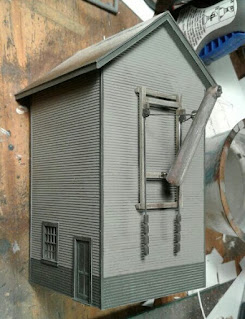

A few weeks ago, I completely redrawn artwork from CDS in Adobe Illustrator to transform them in good quality decals. It took a lot of time, but was well worth the effort. One of the first car I decided to build was the Canadian Northern refrigerator car. It had a simple paint scheme and, according to pictures, was very, very close to a Roundhouse 36ft reefer.

It was a fun build and I improved the model a little bit by addind new metal stirrups, roof grabirons, brackets and fishing line truss rods with Tichy turnbuckle. Brake details are Tichy too. In hindsight, I should have taken a hour to remove the molded grabirons, but I was too lazy for that. My mistake. The car is currently riding on old Roundhouse archbar trucks, but I'm planning to swap them later with Tahoe or Bowser ones when I'll purchase some.

Painting was straighforward, but I made sure to bleach the roof as much as possible in previsioon for weathering. On the roof, many boards were repainted individually in slightly different shades of brown. If you look at old pictures, wooden roofs are always a patchwork of colors because wooden planks were heavy maintenance and required replacement and paint touch up frequently.

When done with the coloration, I applying AK Interactive Streaking Grime wash over the model and removed the excess with odourless thinner. The goal was to make the plank texture pop up a little bit so the car would look more realistic. All that was done prior to decalling because I've learned from experience that your should always pre-shade your models. Also, sometimes washes on light colored cars pick up the decal edges, creating horrible weathering patterns.

|

| In Canada, reefers were used also as insulated cars. The trap was for a charcoal heater. |

When everything was completely, I sealed the model with a coat of gloss coat, then with a layer of dullcote to kill the shine. As Hunter Hughson likes to remind us, dullcote is basically a solution made of talc and a carrier. It can't act as a durable protective coat. That's why I've been gloss coating all my models since a few months to improve durability. The dullcote is just there for the look.

|

| The prototype |

At this point, I consider the model ready for the layout, but it hasn't been weathered yet. Road grimes will have to be added and some shadows added around the molded grabirons to make them look better. Overall, I'm quite glad with this model and my only real criticism is the decal. When applying them, it became evident the old CDS artwork was derived from a picture I found online. It's highly skewed. I used Photoshop to rectify the picture and superimposed it over the artwork. Found out the lettering is far too wide compared to the prototype and dimensional data is too tall. Given the limitations when this artwork was drawn in the 1970s and 1980s, it's excellent. But honestly, I'll need to redraw it using the rectify picture to correct the many discrepancies. That said, I guess most people won't notice!

Next time? More Canadian Northern rolling stock and many other surprises.