Monk Subdivision is progressing at a decent pace right now. I’m currently fine tuning the staging yard design and cutting plywood for it. In the recent days, I did a few experiments with tracks that completely changed my approach to what I’m about to do.

The biggest

concern about the hidden staging yard is that vertical clearance is minimal. We

are talking about 6” at best here which isn’t close to any recommended

practice. The answer is simple, how do

you deal with access, derailed equipment and cleaning the tracks? I wish I had

more vertical clearance, something close to 10” or 12”, but it isn’t possible.

I have no place to spare for a helix and I want to keep my grade under 1.5% at

any cost to maintain a good performance for my steam locomotives. With that

known, I have to design my way around that hurdle.

The first

thing is to make the foreground and background on the upper deck partially

movable so I can access the tracks in case of an incident or simply for

maintenance. This is even more important where turnouts are located. If

possible, I wish to put turnouts where they will be easier to access. On the

left, it means I can place a few ones under the hill in the foreground. The

hill will be a good excuse to have an access slot in the fascia so we can

visually monitor what’s going on in the staging. Other turnouts on the left

will be located after the big curve because they will clear the lower cabinets

on the wall. I certainly don’t wish to see any complex wiring and controls

there. On the right sides, all turnouts are located against the wall and before

the curve because this is where access is best at all time.

Another big

issue is that my staging yard will need to be built partially on a grade on

both sides. It means most of the yard throats will be inclined. I did some

tests with Rapido Super Continental coaches (my longest and most capricious

cars) and it works fine if the grade is constant and turnouts are far from vertical

transitions. We can consider that a done deal.

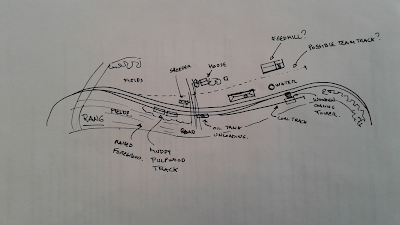

Revised staging plan

Speaking of

unreachable areas, I created alcoves in the upper deck to follow the track

flowing curvature. This is both for aesthetics and to provide a shelf, but also

to make my life easier when handling trains in the yard. I will install a

fiddle track that will be built at the bottom of the left alcove. Trains there

will be both visible and easy to handle. The spot will be useful to build or

break trains there, creating new consists without having to fight under the

upper deck elsewhere. I can also serve as a programming track or to stage the

local freight train. This is the only train that needs to be frequently

changed. This track will be good enough to handle it and I’m planning to

install a series of drawers under the layout right there to make staging

easier.

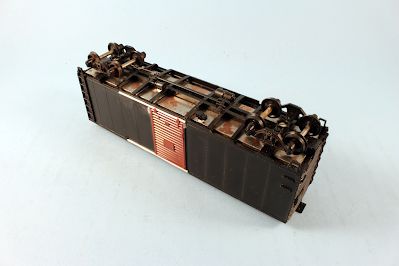

Now, the

last big issue to take care of... Turnouts are a real paint in the proverbial

place. You get short, you lose power, train derails… it’s the main source of

problem on a layout. Now, imagine using them under in hidden places! I can

already imagine the disaster. My original plan called for the use of old PECO

Code 100 Streamline turnouts salvaged from our second club layout. They are

almost brand new and in great shape, but I found out they run a little bit

rough with modern cars, particularly the Rapido ones that start dancing on the

frogs. I also tried with old Blue Box cars and I got the same results. It’s

also very noisy. The turnouts are fine, but on a grade, I don’t trust them. I

did the experiment again with Peco Code 83 turnouts and the ride was much

smoother and quieter. I knew I would have to think twice about using the Code

100 turnouts. Worst, I found out I hadn’t enough of them to build the staging

yard, so I had to make a decision.

This

decision is simple, I won’t use Peco Code 100 turnouts… and will upgrade my

design with Peco Code 83 or Code 70. I prefer more reliable components to be

honest. I see the problem at the club layout and don’t want them replicated

here. Speaking of turnouts, I’ve come to appreciate Peco’s new unifrog design.

I like the idea of being able to upgrade the system later on. The reason is

simple, I have many old DC locomotives I want to use and Unifrog give me the

chance to make it possible to run both DC and DCC. Also, the Unifrog design

comes with continuous solid rail points instead of hinged ones. Much more

reliable for electric current and less prone to derailment.

For these

reasons, I’ve redesigned the yard to only use Peco #6 Unifrog turnouts. It

comes with a price tag, but I know you can’t go cheap with turnouts. Many will

comment that at this point, I should invest in Fast Track jigs and build my own

turnouts. That would be a great idea, but it comes with a serious caveat; I

both suck at mechanical stuff and plainly hate mechanical stuff. I may

understand the general principles, but I’m terrible at implementing them. A

fifty hours spent at the benchwork to build 25 turnouts I know will be less than great doesn’t seem

appealing to me. Bear in mind I totally respect people building their turnouts.

We all know it’s the best way to go, but it’s a red line I’m happy to draw

knowing my strengths lies elsewhere.

With that

said, I’m happy to report the new staging yard is now fully revised and ready

to enter the building stage. It will be quite a challenge since I want to implement

servos for turnout control, insulated staging tracks and IR detection for a

control board that will let me know what’s happening. In the future, I'd like to program the staging turnouts with an Arduino board to make things more intuitive and simpler. I'm not closing the door to automation either since the layout is rather simple.

Staging capacity

This is the most important criteria at the end of the day... How many trains and cars can be staged at once. Since Monk Subdivision saw a lot of traffic back in the days, I wanted enough tracks to hold them all. While I do intend to model mainly the early 1950s, I'll use the layout to run anything in my collection from the 1960s to the 2010s. For this reason, I'll probably run consists made of 3 to 5 locomotives pulling about 30 cars when I'm in the mood for it. Also, some trains on the subdivision were really long. A good example is the Cabot, a passenger train from the late 1960s which can easily be 16 to 18ft long. It's high on my priority list and I really wanted it to be possible.

Using an employee timetable from the 1950s, I've come to this tentative staging scheme which could hold about 140 freight cars and 22 passenger cars at once:

Staging 1: 242 (230) 38 cars (#700 fast freight)

Staging 2: 188 (176) 31 cars (#700 fast freight)

Staging 3: 206 (194) 34 cars (#400 2-10-2 manifest)

Staging 4: 131 (119) 20 cars (#400 2-10-2 manifest)

Staging 5: 127 (115) 19 cars (Fast passenger)

Staging 6: 120 (108) 20 cars (Fast passenger)

Staging 7: 98 (86) 14 cars (#400 2-8-2 manifest)

Staging 8: 95 (83) 14 cars (#400 2-8-2 manifest)

Staging 9: 72 (60) 10 cars (local passenger)

Staging 10: 72 (60) 10 cars (local passenger)