Earlier

this year, I experimented with the idea of finding an efficient way to upgrade Athearn 40ft boxcars without breaking the bank. The idea was not about turning

these cars into prize winning or finescale model (because at the end of the

day, almost nothing would remain from the original shell), but rather to erase

their ubiquitous lineage so they can merge seamlessly into a fleet.

While my

experiment went well, I also encountered a problem: the lack of suitable detail

parts, more precisely doors. As you know, the Athearn doors are quite wrong and

far too short. Back in the 1950s and early 1960s, gimmicks such as operating

doors were all the crazed due to O scale influence. Oversized door tracks and

claws were inevitable and for this reason, the doors were smaller than they

should have been. Add the fact the detail wasn’t great, and you have more than

one reason to scrap them completely.

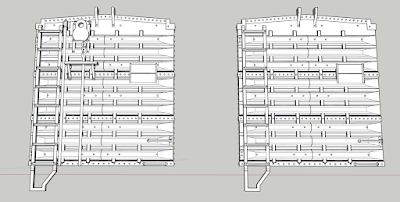

|

| The door before adding rivets and hardware |

Unfortunately,

finding suitable 10’ high 1937 AAR doors is now a fool’s errand. Both Atlas and

Intermountain parts are getting extremely hard to find and they cost quite a

lot for what they are. For these reasons, I decided to design my own doors

using Atlas, IM parts and pictures as blueprints. The process was fast and

about 30 minutes later, I had a nice door ready to 3D print. Given the part

height, it’s about 90 minutes to print, which is more than reasonable.

Later, I

decided to convert other boxcars, namely Roundhouse old 40ft tooling which wasn’t

that great when compared to Athearn. Their later retooled efforts with fixed

doors from the late 1990s and early 2000s were much better. That said, I

decided to do something different and make them early CNR steel automobile

boxcars. These were built in 1936 by NSC and CCF with Murphy flat panel steel

roof and a 10’-0” interior height. By 1946, they were raised by 6 inches to

increase capacity. Since the Roundhouse cars need a lot of work along the sill,

I felt they were perfect for this project since the dubious details had to be

removed anyway.

|

| CN automobile boxcar (credit: Chris van der Heide collection, nakina.net) |

I selected

the ECC cars since they had Dreadnaught ends with the same 5/4 rib pattern than

the Roundhouse cars. NSC had they own distinctive rib pattern (NSC-1) which

would be cool to replicate but using a much better plastic shell has a starting

point.

|

| Filing down raised panels is easier than you would think |

For the roof,

I did a compromise. Since I didn’t want to cut the shell apart, I simply cut

and filed down the raised panels. Real Murphy roofs have a very different way

to be attached to the boxcar sides, but I overlook that detail since it’s not

the goal of this project to be 100% accurate.

Finally, I

need a pair of double doors and decided to tweak my previous 3D design. It took

about 15 minutes to get it right with the correct hardware and the same time to

print.

Another

detail that bothered me was the cast on ladders. Athearn ladders are decent for

what they are, but the Roundhouse ones are thick and looks wrong at first

glance. Also, the lower rung is missing. I gave it some thought and ask myself

if it was efficient to remove a ladder and replace it or if it was better

trying to upgrade it by adding the missing rung. I didn’t want to waste A-Line

stirrups if possible.

|

| Roundhouse ladders are just plain wrong and unsalvageable...

|

I tried to improve

the molded ladder but results were poor and it was a slow process. In a word,

it was counterproductive. Then, I chiselled the ladder off and found out it

took about one minute per ladder, which was much more efficient. Now, it was

time to design a replacement ladder with 8 rung and an attached stirrups has

was customary in Canada back in the days. To keep the car level of detail

consistent, I used the same design parameters that Irv Athearn set for his

boxcars 70 years ago. I could have made very fine ladders, but what I needed

were ladders that would blend with Athearn and Roundhouse cars. In my mind, you

can’t have finescale ladders with chunking ends. Make it all the same and it

will look better. If you go all in with prototypicalness, embrace it. If you

want to stay middle of the road, be consistent too.

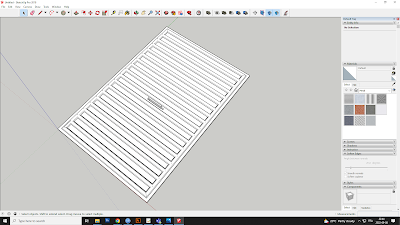

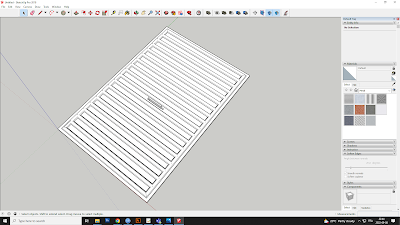

Designing

the ladder took about 5 minutes at best… it was a breeze. The result was nice

because now the boxcars had that distinctive Canadian vibe as if Roundhouse had

released, in the 1970s, a real Canadian automobile boxcar.

I won’t

pretend these cars are prize winning models, but in a fleet, they do a fine job.

In themselves, they have no merit, but you can convert about 4 of them over the

course of a few evenings without turning mad or loosing hairs.

Furthermore,

they may be a little bit incorrect, but they try to stay true to prototype as

much as possible. And finally, the key is to bring them to life by applying

realistic weathering. As I get more experience in this hobby, I’m learning

everyday that right colors and right weathering should be among the first

criteria to attain realism. Realism and accuracy are somewhat different in my

mind. They work together, but I would say that realism is what makes a model

plausible while accuracy is the measure by which the model is close to its

prototype. There is no hard line between both concept and each has to chose

what is adequate for his purpose.