|

| The station is 3D printed and the freight house is scratchbuilt |

The 3D

printing debate is still raging, with some purists considering it a form of

repudiation of craftsmanship. Others, on the other hand, like any new technology,

consider it a panacea and forget it’s only one tool in the toolbox. More

nuanced point of views do exist too and a few do recognize they don’t have the

desire to develop the skills required to learn how to be efficient with 3D

printing. I won’t argue with that. It can be a monumental waste of time in

certain circumstances.

|

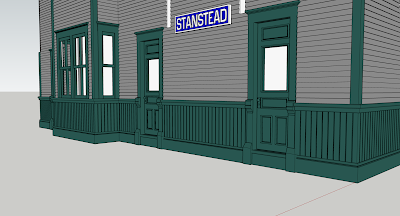

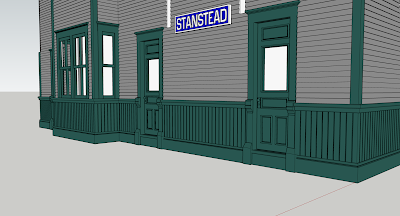

| 3D modelling enables you to go fully prototypical with details |

As an

experiment, I decided to 3D print Stanstead station. It was not my initial plan

and to be honest, I had already purchased clapboard siding sheets for the project.

However, after building a cardboard mockup, I quickly found out getting the

roof perfect was hard. Also, replicating the intricate mouldings and plinths on

the wainscotting would be almost impossible. As for doors and windows, it was

all compromises which I didn’t want to make. I thought 3D printing would be a

suitable way to get things done quickly and accurately.

|

| Before printing the full station, I printed a slice of it. |

It took

half a day to create the 3D model. I simply extruded the clapboard profiles,

created window and door types and added a few details. I elected to print the

walls and roof as a monolith and created holes so the resin could flow out of

the station as it printed (pooling resin in a closed volume is never a good idea).

Roof brackets were printed individually thought for ease of printing and

painting. My theory that it should be printed like a freight car shell. The roof

eaves would be added later (printed or styrene). The model took 4 hours and

half to print and had a cost of a few dollars. Assembly was straight forward,

details accurate and geometry relatively straight. I modelled the interior

partitions walls, so the model was already reinforced against warping which is

a real issue with resin.

|

| The station is printed as a single part to make it sturdy |

Painting

was fast and honestly; I consider printing the station was a good decision

overall. The design and printing phase was enjoyable, took less time than a

full scratchbuilt and was much more accurate, enabling me to recreate intricate

architectural details that Tichy and Grandt don’t offer.

|

| A partially painted station to see how it looks on the layout |

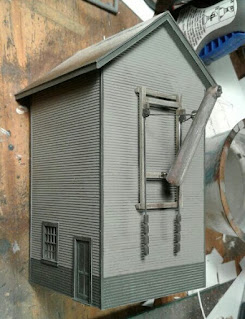

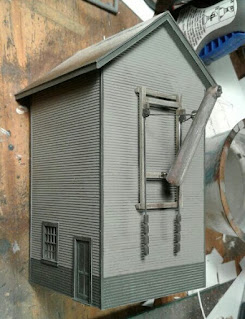

When came

time to build the water tower and freight house, I decided to go full

scratchbuilt with styrene. These structures are simpler and use basic components.

I used Tichy windows and doors, all the rest was crafted by hand, including the

large doors. It took about 8 hours to put together the freight house and maybe

3 hours for the water tower. These structures involved a lot of guesswork since

I had only poor photographic evidence to work with. It consumed a lot of time

even if they were simpler than the station.

|

| After 8 hours and lots of compromises |

|

| Custom distressed wooden planks are fun to make by hand |

|

| The tower was straighforward and enjoyable |

Was it

enjoyable? The water tower was… but the freight station was not as I had to

make a lot on annoying compromises to fit the commercial detail parts I used.

At the end of the day, it made the freight house look a little bit awkward.

Since I didn’t have a 3D model, it was impossible to validate my design choice

and the building proportions, which was a hindrance until the end. Even with a

coat of paint, I’m not sure I like the building. I may simply print it from

scratch and sell the original styrene one point in the future. Even if I would scratchbuild

it, I think creating a 3D model helps to iron out the details as it’s a useful

mockup that can be modified and improved.

|

| The freight house after some paint. |

At the end

of the day, I don’t see any clear winner. Each technique has its pros and cons.

3D printing is fast and accurate if you know what you are doing. It’s cost

efficient too, but produce a lot of toxic waste and fumes that must be handled

carefully. That’s an aspect I hate of 3D printing. Scratchbuilding is cool, fun,

intuitive, but can lead to unsightly results. It’s also more costly in material

(though cheaper since a 3D printed is not cheap), more involving and, depending

on if you work with commercial parts, less accurate. When I look at it, I

consider each technique has its merits, and to be honest, they are complementary.

The water tower sprout and freight house chimney are good examples of things

that are better printed. Windows and doors are also nice to print since it

removes the accuracy issues caused by commercial parts.

|

| Completed tower with a Heljan water sprout |

I’m quite

glad to have experimented both techniques at the same time on the same type of

objects. It really put things in perspective.